HYPROVIDE®

A-SERIES

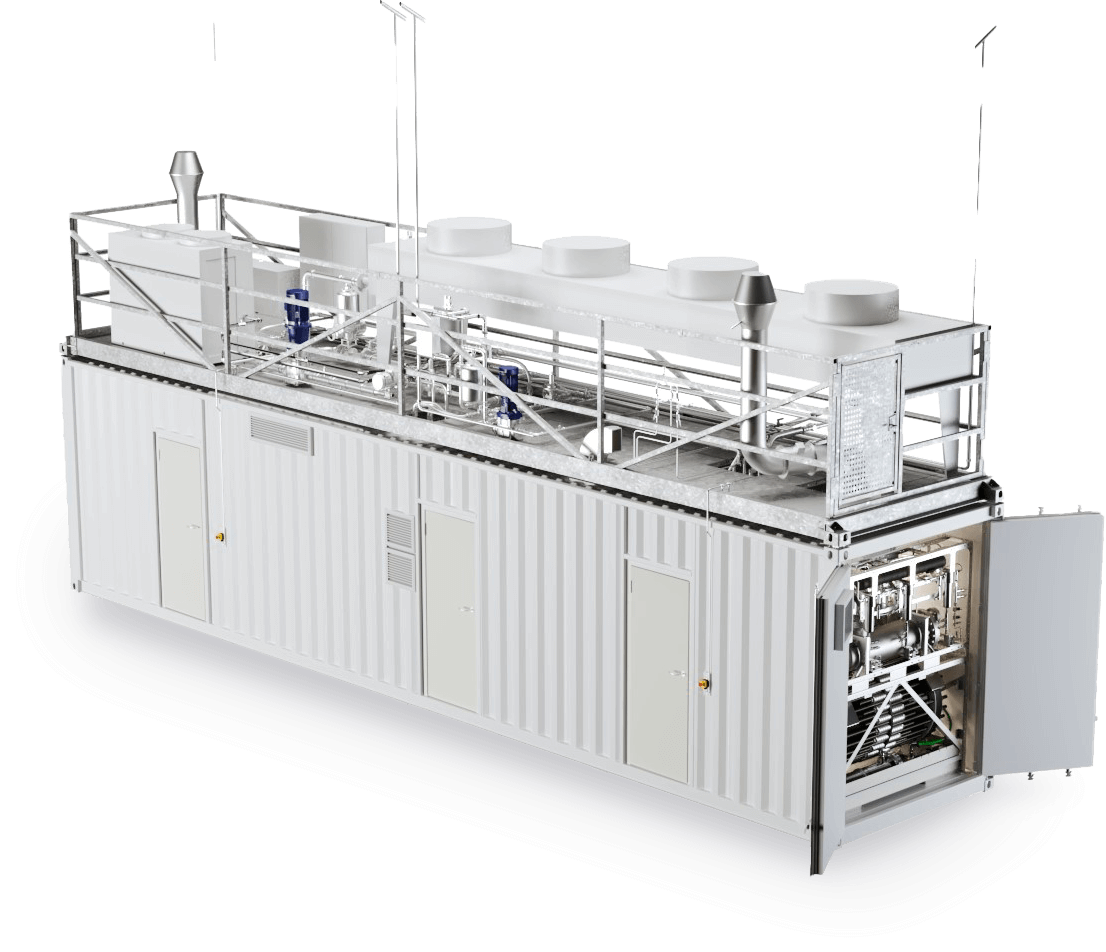

A modular, containerized, plug-and-play electrolysis solution.

- Hydrogen production: 180 Nm³/h (16.2 kg/h)

- Hydrogen gas purity: 99.998%

- Cell stack efficiency: 53.0 kWh/kg Hydrogen

- Outlet pressure: 30 bar(g)

The top frame contains a number of components needed for process control of the gas generation, efficient cooling and ventilation, nitrogen inlet and hydrogen outlet.

Within the HyProvide® A-Series, you will find all the components necessary for hydrogen generation: full water treatment and pressurisation, stack power supply for one or two stacks, main controls, and a data collection point. The unit is divided into three rooms: two process rooms and one power room, while the 20-ft version is divided into two compartments: one for processing and one for power.

All main interfaces, such as power, water, nitrogen and hydrogen, are accessible from the outside of the container

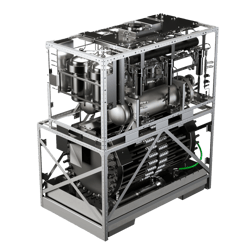

The heart of the HyProvide® A-Series unit is the process modules. The process modules are integrated into a separate compartment at the end of the container, where they are easy to access and maintain.

With a very efficient stack and BoP integrated, the HyProvide A-container provides very competitive electrolysis at high pressure.

Inside the HyProvide® container unit, you find all the components necessary for water treatment and pressurisation, power supply, main controls and processing separated into three compartments.

The two process modules are placed at each end of the container in their dedicated process room.

The power connection box and water inlet are accessible from outside the container.

The cooling systems, the ventilation outlet ducting, the hydrogen and oxygen vents, and the roof module are placed on the top frame of the container.

Experience the A-Series in action

Live multi-MW use case in UK

Explore this captivating video to see the GHS A-Series electrolysers in action, providing GeoPura, our UK partner, with sustainable hydrogen for their innovative Power-to-Power solutions.

System Specification

Input details

Output details

Operational details

Our team is standing by to assist you

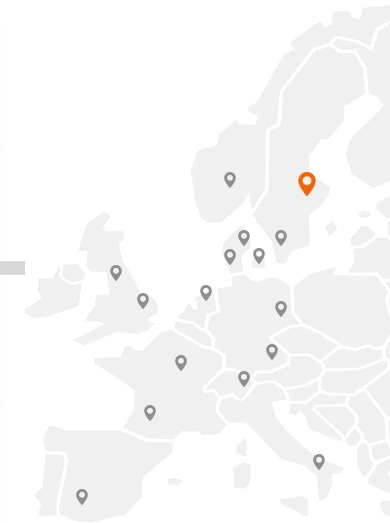

Selected projects

in Europe

GEOPURA™

The first three of 15 HyProvide® A180 electrolysers are already commisioned and producing green hydrogen in the UK. This green hydrogen will fuel a new generation of power generators for various sites in the UK.

Read more

SIEMENS GAMESA

A HyProvide™ A60 electrolyser for on-site hydrogen generation. Complete turnkey delivery and commissioning by GHS.

Read more

NILSSON ENERGY

A HyProvide™ A60 for the production of green hydrogen on-site for a hydrogen refuelling station – powered by solar energy to make 100%...

Read more

Alliander

3 x A90 HyProvide™ Electrolyser for Ecomunitypark in the Netherlands. To produce hydrogen on-site from excess renewable energy.

Read more

Ørsted

A plant will be built around five Hyprovide® A90 electrolysers powered by two offshore wind turbines.

Read more

WENGER

Three GHS HyProvide™ A90 electrolysers to be deployed at an electrolyser test field in Bremerhaven, Germany.

Read more

Liquiline/HYDS

A long-tem project with Liquiline/HYDS to deliver and operate electrolysers for commercial production of green hydrogen using using GHS' versatile A180 electrolyser.

Selected projects

in Europe

GEOPURA™

The first three of 15 HyProvide® A180 electrolysers are already commisioned and producing green hydrogen in the UK. This green hydrogen will fuel a new generation of power generators for various sites in the UK.

Read more

SIEMENS GAMESA

A HyProvide™ A60 electrolyser for on-site hydrogen generation. Complete turnkey delivery and commissioning by GHS.

Read more

NILSSON ENERGY

A HyProvide™ A60 for the production of green hydrogen on-site for a hydrogen refuelling station – powered by solar energy to make 100%...

Read more

Alliander

3 x A90 HyProvide™ Electrolyser for Ecomunitypark in the Netherlands. To produce hydrogen on-site from excess renewable energy.

Read more

Ørsted

A plant will be built around five Hyprovide® A90 electrolysers powered by two offshore wind turbines.

Read more

WENGER

Three GHS HyProvide™ A90 electrolysers to be deployed at an electrolyser test field in Bremerhaven, Germany.

Read more

Liquiline/HYDS

A long-tem project with Liquiline/HYDS to deliver and operate electrolysers for commercial production of green hydrogen using using GHS' versatile A180 electrolyser.

.png)

.png)

#8 reasons to choose

our electrolysers

Mature Technology

Our products are built on commercially proven pressurised alkaline technology.

High Efficiency

One of the most efficient solutions on the market with competitive energy to hydrogen conversion.

Modularity

Modular solutions that are suited for rapid scale-up, clustered solutions and serial production.

Dynamic Operations

The electrolysers are designed for renewable energy and operate dynamically at variable load rates.

Durability

High durability (10+ year stack durability)

and system uptime.

High Output Pressure

The +30 bar hydrogen output pressure allows for a small product footprint and lower compression costs.

Compact Design

Small footprint due to compact modular design increasing number of applications.

Versatility

Its versatile design allows for application across many different market segments for green hydrogen production.

Service adjusted

to your needs

Long-term performance guarantees

Delivering business case certainty and lifetime asset optimisation.

Remote monitoring and support

Remote troubleshooting and operational excellence based on data from online monitoring, field force experience, and R&D learnings.

Spare parts offerings

Leveraging digital tools to offer superior convenience and delivery speed in the supply of spare parts

Customer care function

Providing superior customer journey (performance reporting, issue and request handling, invoicing)

Asset analytics capabilities

Building data infrastructure and analytics (actuarial) as an enabler for performance guarantees